CNC Machining Company: A Game Changer in Metal Fabrication

CNC machining is no longer just a manufacturing process; it has become a cornerstone of modern metal fabrication. As industries evolve, the demand for high-quality, precision-engineered parts has skyrocketed. This article delves into the significance of cnc machining companies, focusing on how businesses like DeepMould.net are leading the charge in this competitive landscape.

Understanding CNC Machining

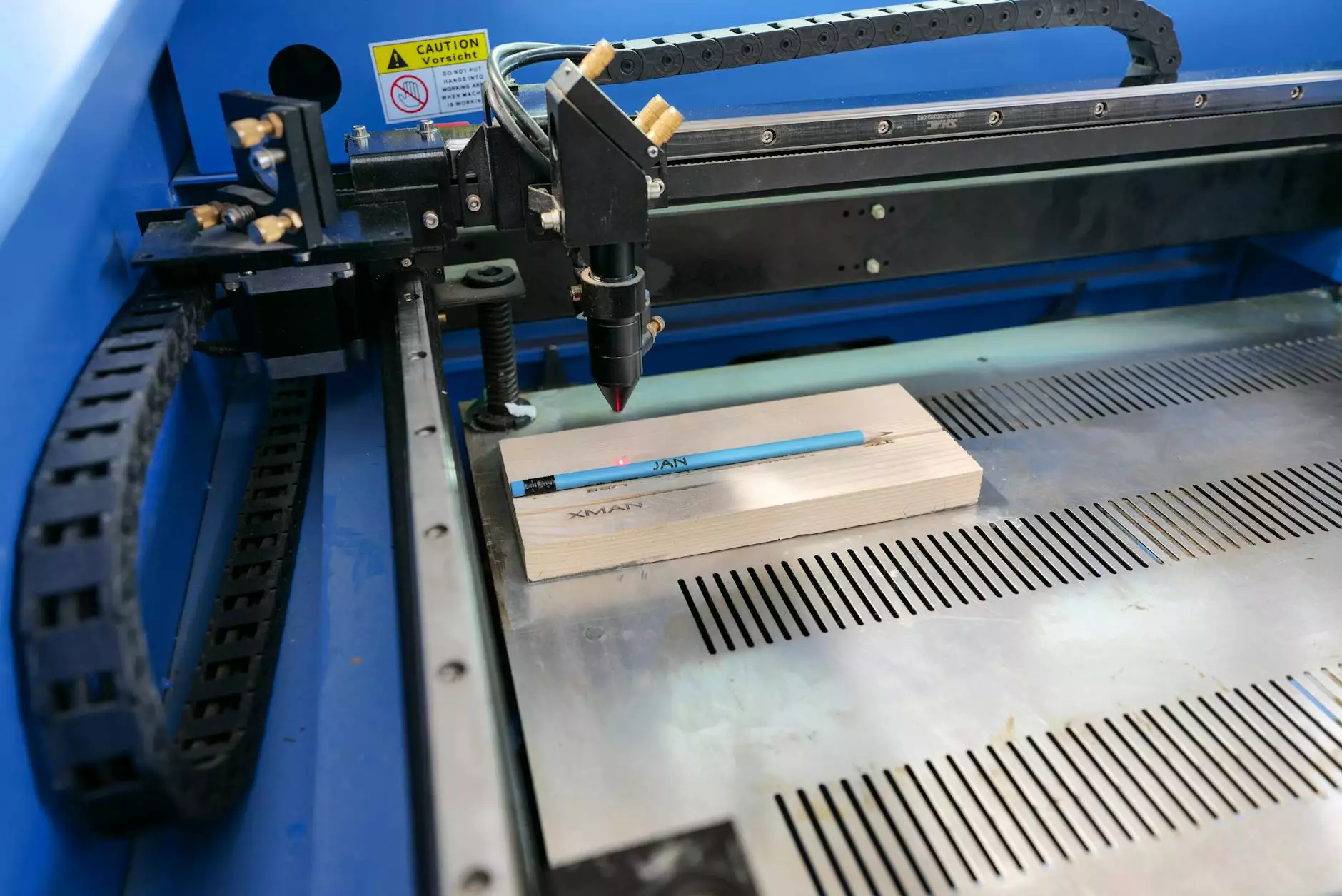

CNC machining, or Computer Numerical Control machining, refers to the automated control of machining tools via computer systems. This technology allows for the precise manufacturing of complex parts and components, vastly improving both accuracy and production efficiency compared to traditional machining methods.

The Process of CNC Machining

The CNC machining process involves several key steps:

- Design Creation: Using CAD (Computer-Aided Design) software, engineers design 3D models of the parts required.

- Machine Programming: The designs are converted into a language that CNC machines can interpret—commonly G-code.

- Material Setup: High-quality materials, typically metals such as aluminum, steel, or titanium, are prepared for machining.

- CNC Machining: The CNC machine executes the programmed instructions, cutting, shaping, and finishing the material into the desired part.

- Quality Control: Each part undergoes rigorous inspection to ensure it meets exact specifications and tolerances.

Why Choose a CNC Machining Company?

Working with a dedicated cnc machining company like DeepMould.net comes with numerous benefits:

1. Precision Manufacturing

One of the core advantages of CNC machining is its ability to produce parts with unmatched precision. This level of accuracy is crucial in industries such as aerospace, automotive, and medical – where even the slightest deviation can lead to significant issues.

2. Increased Efficiency

CNC machines operate continuously with minimal downtime, significantly increasing productivity. Businesses can achieve higher output levels without compromising on quality.

3. Cost-Effective Production

Although the initial investment in CNC technology may be substantial, the long-term savings realized through reduced labor costs and material wastage make it a financially viable option.

4. Versatility and Flexibility

Modern CNC machines can work with a diverse range of materials and can be easily reprogrammed for different tasks, allowing companies like DeepMould.net to cater to various client needs.

Key Applications of CNC Machining in Metal Fabrication

The industrial applications of CNC machining are vast. Below are several sectors where this technology plays a pivotal role:

- Aerospace: Manufacturing intricate parts that need to withstand extreme conditions.

- Automotive: Producing high-quality engine components and body parts.

- Medical: Creating precise instruments and implants for healthcare professionals.

- Electronics: Crafting components for devices that demand high precision.

- Custom Fabrication: Providing tailored solutions for unique client demands.

DeepMould.net: Leading the Way in CNC Machining

Among the various cnc machining companies, DeepMould.net has established itself as a frontrunner. Their commitment to quality, customer satisfaction, and technological advancement sets them apart in the metal fabrication industry.

Quality Assurance

At DeepMould.net, quality assurance is paramount. They implement strict quality control measures at every stage of manufacturing, ensuring that all products meet or exceed industry standards. By using advanced inspection techniques, including CMM (Coordinate Measuring Machine) testing, they guarantee precision and reliability in every part produced.

Innovative Solutions

Innovation is at the heart of DeepMould.net's operations. They continuously invest in state-of-the-art machinery and technology to enhance their CNC machining capabilities. Their skilled workforce is regularly trained in the latest methodologies, ensuring that the company stays ahead of industry trends.

Customer-Centric Approach

Understanding client needs is crucial for any successful business. DeepMould.net excels in providing personalized services, helping clients develop custom designs and solutions that fit their specific requirements.

The Future of CNC Machining

The future of the cnc machining company landscape looks promising, with several trends shaping its evolution:

1. Automation and Robotics

As automation advances, the integration of robotics with CNC machining will further enhance production capabilities, reducing human error and increasing efficiency.

2. Smart Manufacturing

The rise of the Internet of Things (IoT) is set to transform CNC machining, with smart machines being able to communicate with each other to optimize production processes.

3. Sustainability

As industries become more environmentally conscious, CNC machining companies are prioritizing sustainable practices, such as reducing waste and utilizing recyclable materials in their processes.

Conclusion

In conclusion, CNC machining companies like DeepMould.net are revolutionizing the metal fabrication industry with their precision, efficiency, and innovative solutions. As the demand for high-quality manufacturing continues to rise, engaging with these specialized companies is more important than ever. By understanding the benefits and applications of CNC machining, businesses can better navigate the complexities of production and gain a competitive edge in their respective markets.

Whether you’re in the aerospace, automotive, or any other sector requiring precision engineering, consider partnering with a leading CNC machining company. The path towards superior quality and efficiency starts here.